High-throughput rotational laminography

3D inline wafer-level advanced packaging inspection

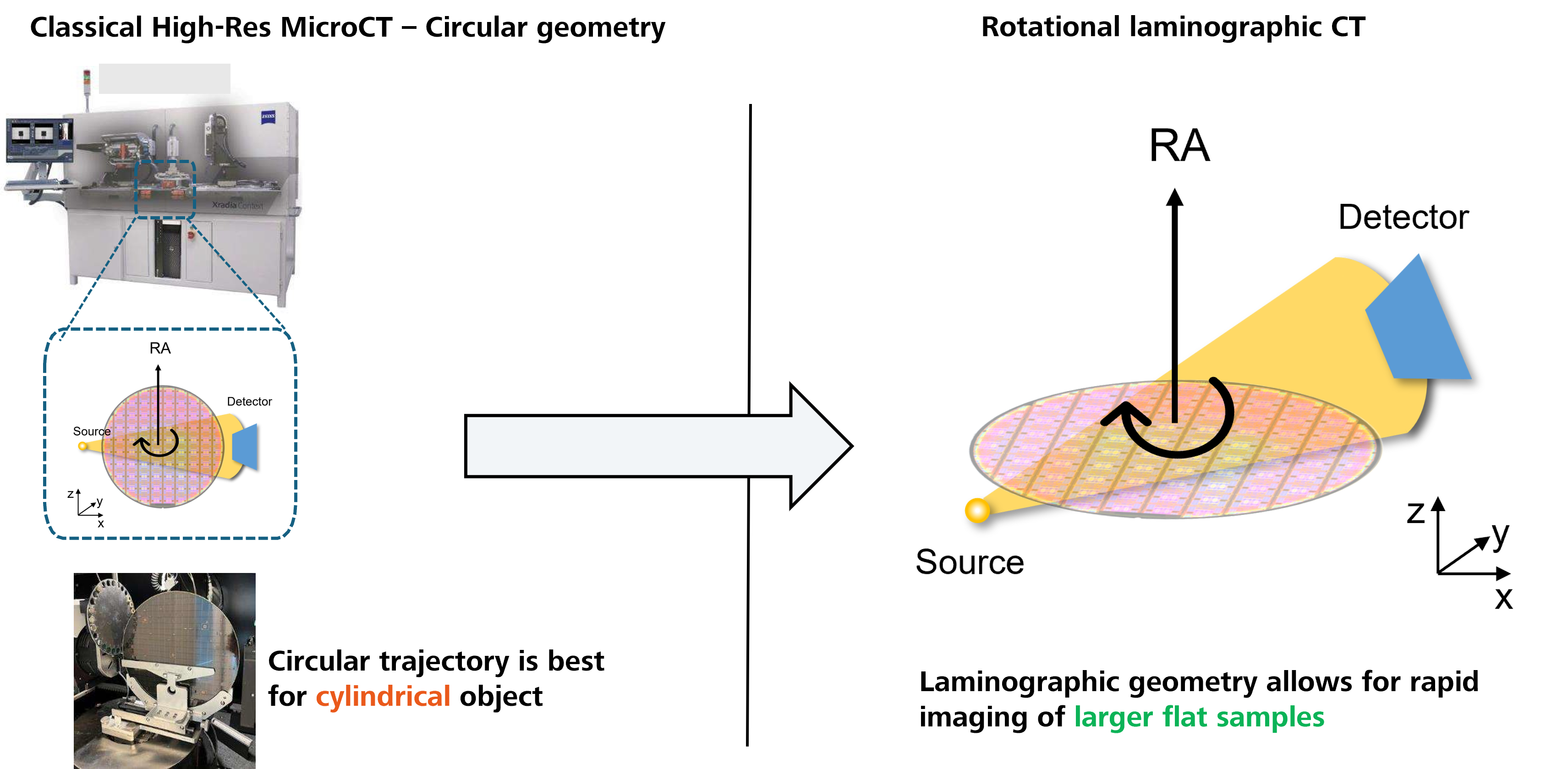

Three-dimensional integrated circuit (3D IC) packaging offers superior performance and energy efficiency over 2D IC packaging but requires reliable, high-throughput in-line inspection to detect defects like misaligned interconnects and voids. X-ray computed laminography (CL) is an effective technique for high-throughput volumetric imaging of large, planar samples, which is well-suited for wafer-level 3D IC packaging inspection.

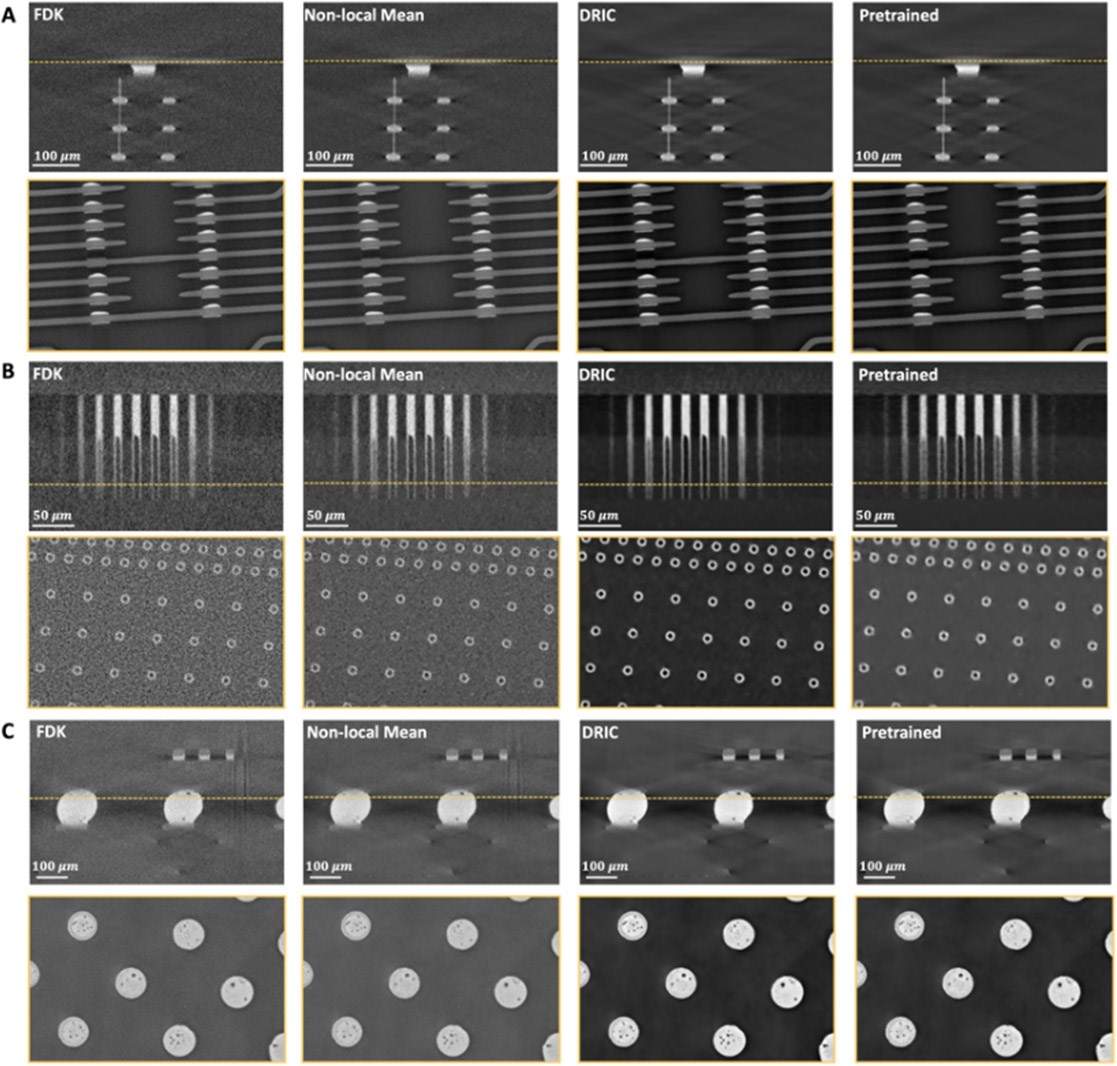

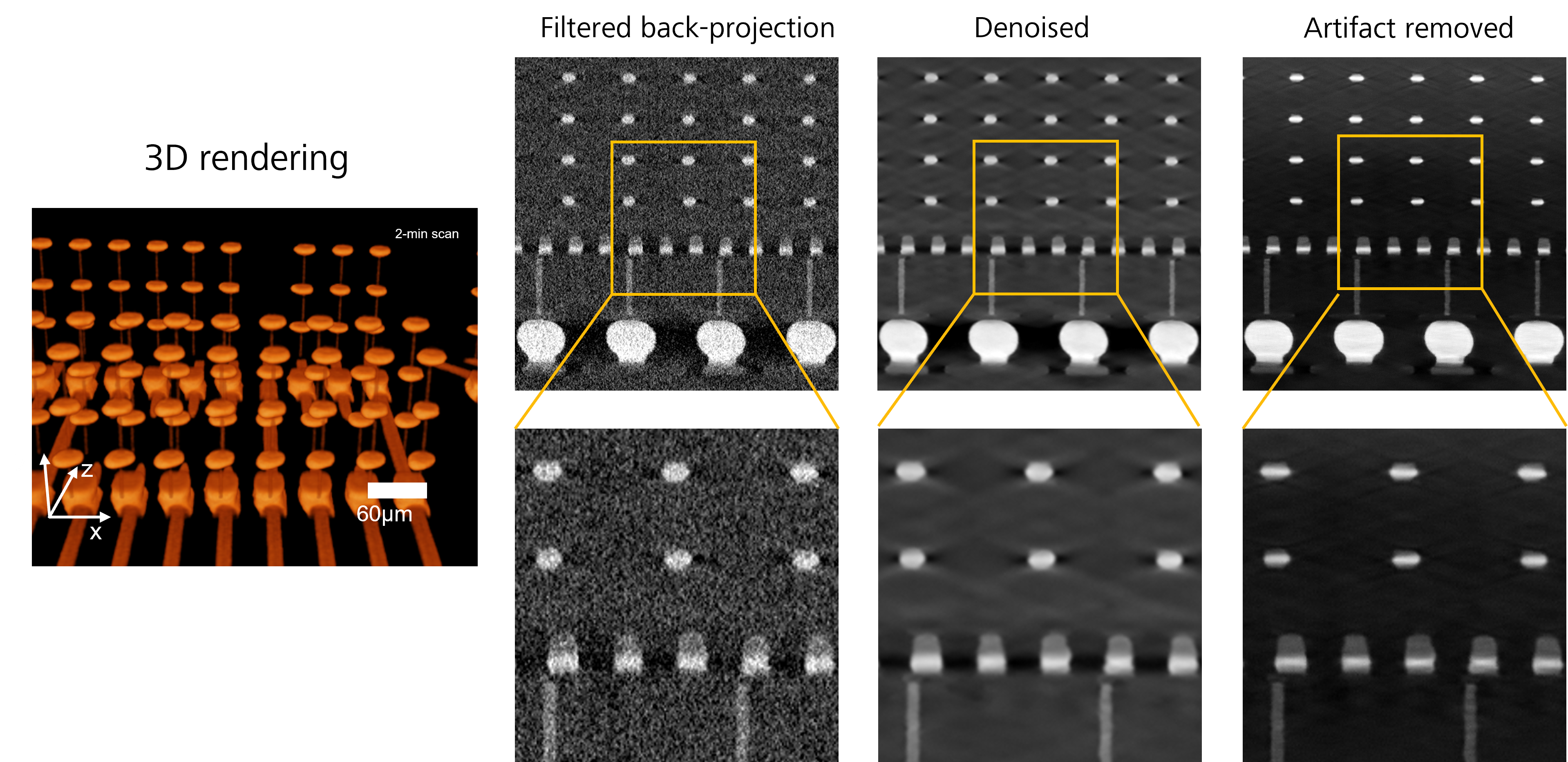

However, due to stringent time requirements demanded by inline semiconductor manufacturing inspection applications, which typically require completing inspection per region-of-interest (ROI) within minutes, the shot-noise limited scans tend to resulting in reconstructions that are too noisy for robust downstream metrology and defect analysis. To meet this challenge, we developed a self-supervised workflow to create a generalist deep learning model for high-resolution (~2.3 gigavoxels per scan) volumetric CT image denoising by pre-training the model on a large number of semiconductor packaging datasets. We showcase that the generalist model has superior zero-shot denoising capability on a varity of semiconductor packaging samples.

In addition, because computed laminography geometry violates Tuy’s data sufficiency condition, reconstructions typically exhibit butterfly-like cone-beam artifacts. To address this, we present a self-supervised deep image restoration workflow that produces noise-free, artifact-free volumetric reconstructions. The core of our proposed pipeline is an unbiased progressive artifact removal algorithm designed to suppress laminographic artifacts. These artifact-corrected volumes are then used to train a deep image restoration network, improving image quality without increasing inference time. We demonstrate the efficacy of this method on a variety of samples scanned with an in-house prototype system.

Further reading

Xu, Shiqi, et al. “Self-supervised deep image restoration for x-ray computed laminographic tomography.” Developments in X-Ray Tomography XV. Vol. 13152. SPIE, 2024.

Guo, Zijing, Xu, Shiqi, et al. “The Role of Pretraining in High-Throughput Laminography Restoration.” Microscopy and Microanalysis (2025): ozaf048-984.